Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

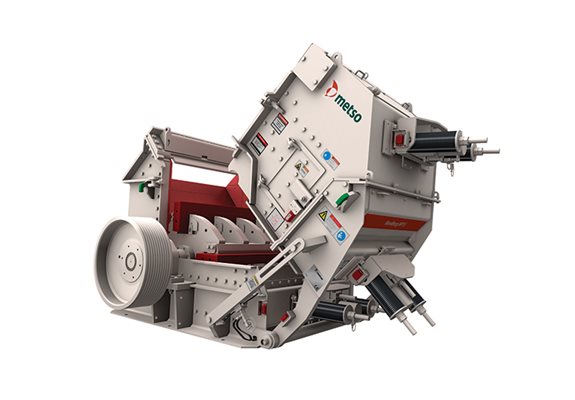

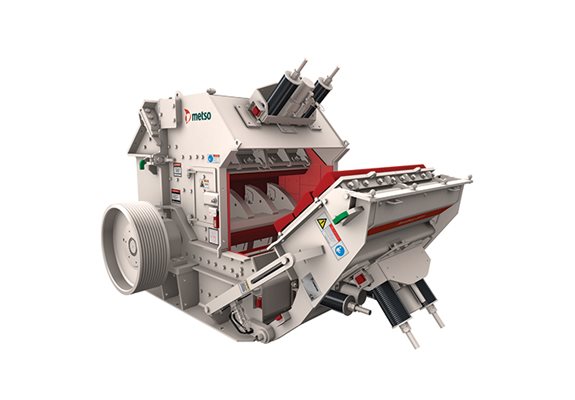

The impact crusher is suitable for various materials, and it is more effective in processing materials with high water content, which can effectively prevent material clogging. It can also adjust the discharge granularity conveniently and flexibly. At the same time, the spare crusher wears less, and the metal utilization rate is high, so it is easy to replace. Simplicity and correspondingly lower maintenance costs. Due to the above advantages, the impact crusher plays an irreplaceable role in ore crushing.

Operating procedures for impact crushers and impact crushers:

1. Regularly check whether the protective cover of the transmission belt and the coupling is loose, and whether the anchor bolts are loose, otherwise they must be tightened in time. Regularly check the temperature and sound of the bearings, the vibration of the crusher body, and promptly notify the relevant personnel for inspection if there is any abnormality.

2. When the impact crusher has abnormal crushing sound during operation, stop the machine immediately and notify the relevant personnel and supervisor to conduct a detailed inspection.

3. Pay attention to observe whether there are large pieces exceeding the feed particle size requirements in the discharge pit. If found, stop the operation of the feeder and crusher immediately, and then operate normally after processing.

4. When inspecting the impact crusher, wear labor protection equipment correctly and be careful.

5. Regularly check the wear of the impact crusher hammer head, observe whether there is any crack in the hammer head, and whether the hammer head connection is vibrating, and deal with it accordingly and report it to the superior.

6. The particle size of the material crushed by the impact crusher is not allowed to exceed the specified maximum particle size.

7. Pay attention to observe the operating sound of the impact crusher, check whether the hydraulic and lubrication systems are normal, and stop the machine in time if any abnormalities are found.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.