Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

![]() December 13, 2022

December 13, 2022

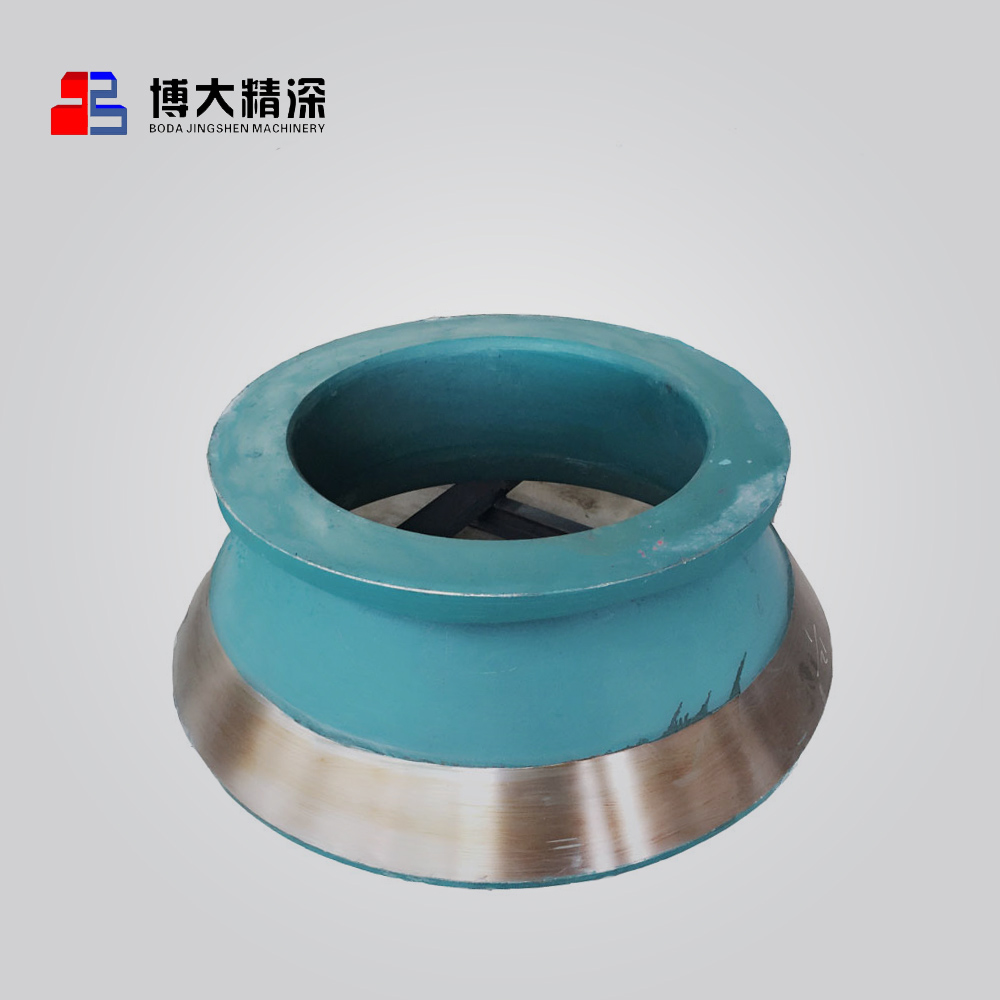

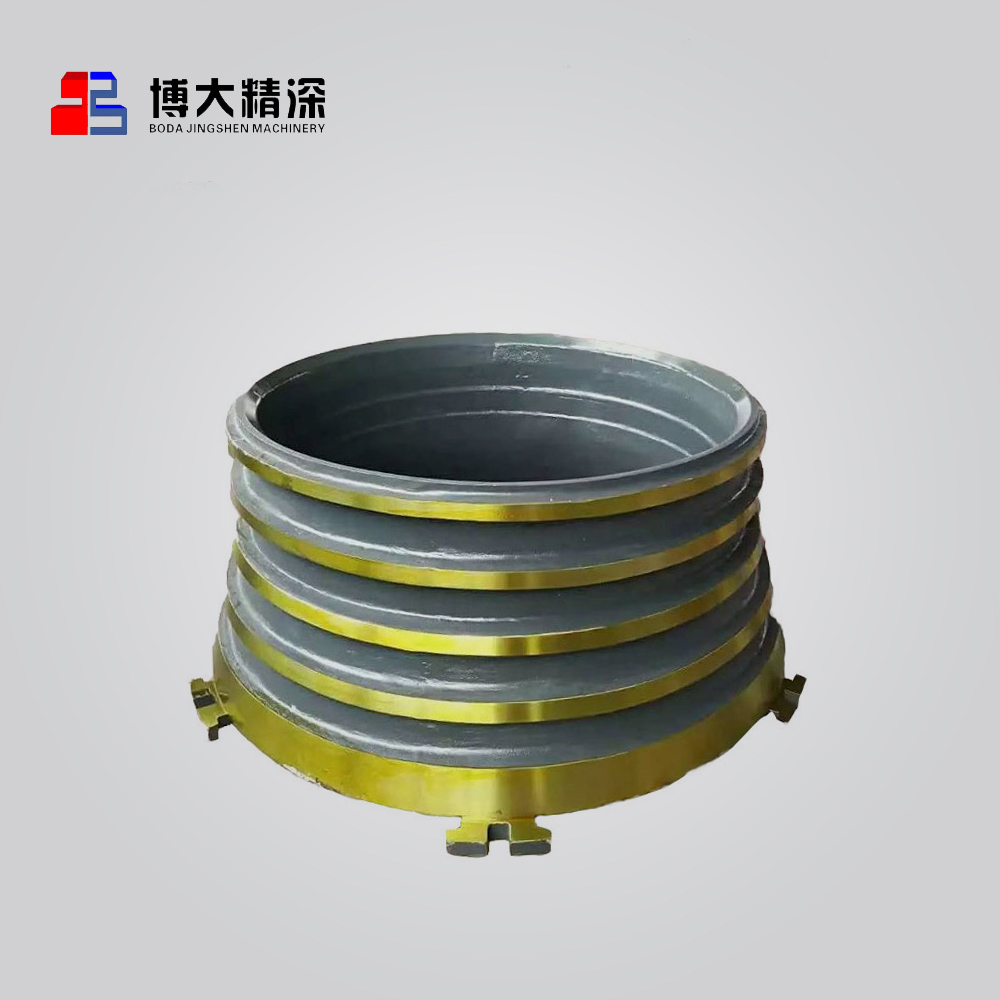

Basic Information Of Cone Crusher

Cone crusher is a crusher suitable for metallurgy, construction, road construction, chemical and silicate industries. According to the different crushing principle and product particle size, it is divided into many models. Crusher is widely used in mining, smelting, building materials, highway, railway, water conservancy and chemical industry and many other departments. Cone crusher has large crushing ratio, high efficiency, low energy consumption, uniform product particle size, suitable for medium and fine crushing of all kinds of ores and rocks. The models are mainly divided into SMG series, spring type and HPC series. Their working principle and structure are introduced respectively. The development history, working principle, composition, influencing factors, technical advantages, operation matters, common faults and inspection and maintenance of cone crusher are also introduced in detail.

The above is the Basic Information Of Cone Crusher we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.